Visual Analysis Device

Delivering standardised, rapid, and accurate analysis

How it works

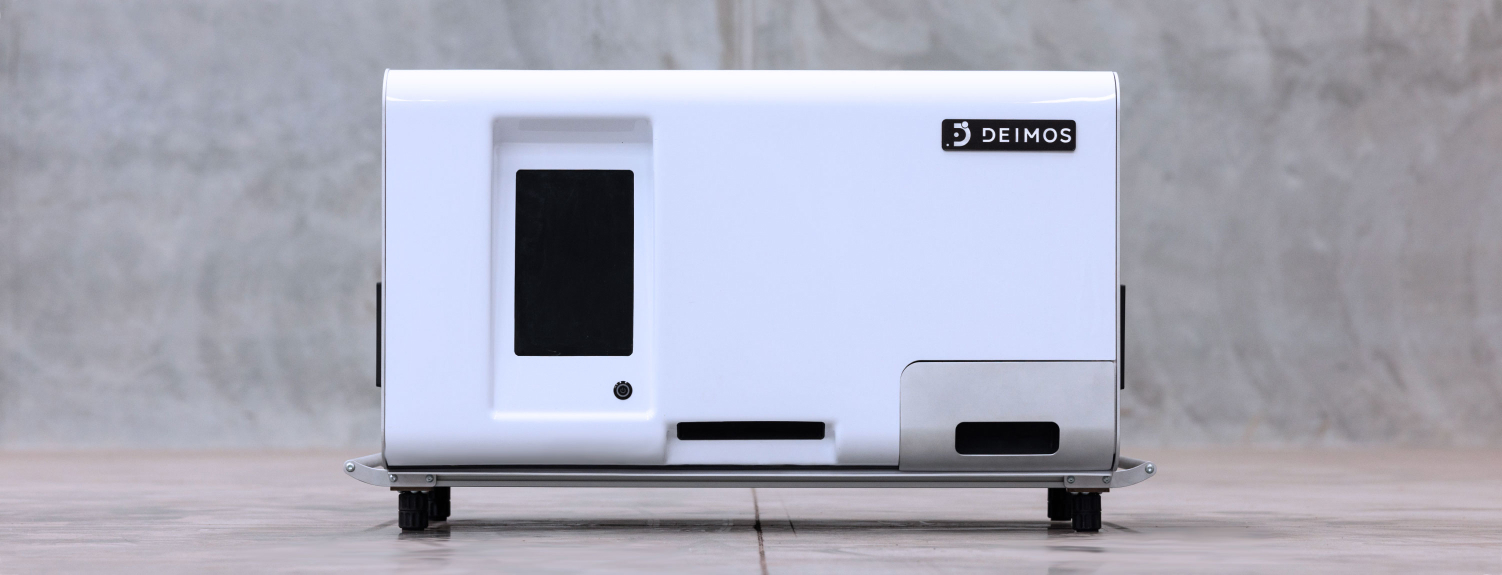

The Visual Analysis Device is a compact device designed to streamline laboratory or sampling hut processes.

The device efficiently handles processing a standard grain sample accomplishing the visual analysis in just 2 minutes. Its printer-sized form conveniently rests on the bench, offering standalone processing of results. Notably, the device has a self-cleaning mechanism utilising contactless high-pressure air. Additionally, it boasts automatic calibration features, guaranteeing consistent and accurate measurements and with user-friendly attributes, marking a significant advancement in laboratory equipment.

01

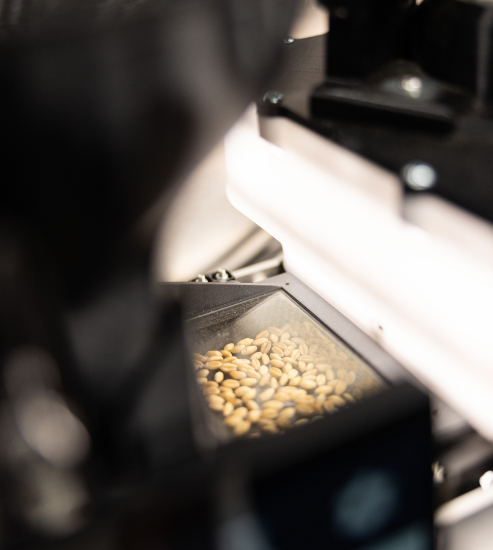

GRAIN SAMPLE PLACED

02

VARIETY SELECTION

03

VISUAL QUALITY ASSESSMENT

Visual Analysis Device

- High speed processing / full sample capture

- Double sided image capture

- Repeatable, and verifiable results

- Interactive touch screen

- Individual object analysis

- Artificial intelligence & machine learning

Features

High speed processing

Rapid visual sample processing boasts an average turnaround time of 10.000 kernels in less than 4 minutes. The machine accelerates the assessment process and significantly avoids incorrect grain classification by thoroughly examining the entire sample, setting a new standard for speed, efficiency, and comprehensive analysis.

Double sided image capture

This feature can capture images from both sides of the grain sample and provides a holistic and comprehensive data analysis. By considering multiple perspectives, the machine enhances the accuracy and depth of its research, ensuring a thoro ugh examination.

Repeatable, and verifiable results

Interactive touch screen

The Visual Analysis Device features an intuitive and interactive touchscreen interface, facilitating user-friendly operation. This interactive platform streamlines the process and allows users to view all visual defects on the screen. It’s a tool designed for seamless interaction, ensuring straightforward interpretation of results.

Individual object analysis

The Visual Analysis Device analyses each kernel within the sample. This level of granularity provides detailed insights into the quality of each grain, enabling precise quality control. Deimos redefines the meaning of accuracy by offering a level of individualised analysis previously unseen in grain assessment technology.

Artificial intelligence & machine learning

A future where innovation, speed, and precision set new benchmarks globally.

Industry impact

We are setting new benchmarks for efficiency and precision in the grain industry through standardised, rapid, and highly accurate sampling methods.

We are redefining the traditional approach to grain sampling. This state-of-the-art technology is poised to streamline and elevate industry practices, ensuring our clients benefit from a standardised, rapid, and incredibly accurate sampling process. By collaborating with CBH Group, we have harnessed the power of automation to enhance productivity and reliability in grain analysis.

FAQ’S

Does it link to the grower app?

How is data security ensured?

What types of grains can the machine analyse?

Does the machine comply with industry standards for grain analysis?

How user-friendly is the machine?

Is the machine capable of providing real-time data and analysis results?

What kind of maintenance is required for the machine?

WA Innovators of the Year: 2024 Rio Tinto Growth Innovation winner

Deimos is an R&D company that leverages computer vision, machine learning and robotics to solve real world problems. Our Visual Analysis Device performs an automated visual assessment of grain, replacing traditional manual methods. The device uses custom designed hardware, deep learning algorithms, automation and software components to provide a comprehensive visual assessment of each grain kernel in a grain sample. The device offers a fast, accurate, and consistent solution for grain quality assessment.